limitation on rockwell hardness test|rockwell hardness test calculation : fabrication How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? . mannitol in the Injection is 10% or less, and not more than 2.5 USP Endotoxin Units per g of mannitol where the labeled amount of mannitol in the Injection is greater than 10%.

{plog:ftitle_list}

A series of washes removes the DNase and other proteins. Highly pure RNA is eluted from the spin cup matrix with a small volume of low-ionic-strength buffer and captured in a .

How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? .In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls.

How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? Interpreting the Results with a Rockwell Hardness Test Chart; How to Calibrate a Rockwell Hardness Tester; What is the Standard for the Rockwell Hardness Test? Advantages and Disadvantages Of the Rockwell Hardness Test. Advantages Of Rockwell Hardness Test. 1. The drawback of the Rockwell test is that the indenter travel is limited to 100 Rockwell points or 0.2 millimeter. This limitation requires different combinations of test force and indenter shapes to accommodate the hardness of all the possible materials to be tested. What Are the Limitations of the Rockwell Testing Systems? The Rockwell Testing systems depend on the material that is being tested including the hardness, thickness, indentation positioning, and scale limitations on the materials that are being tested.TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

rockwell hardness testing procedure pdf

rockwell hardness testing guide pdf

If you are interested in obtaining a complete understanding and holistic background of the Rockwell hardness test, we recommend diving deeper into the ASTM E18-20 Standard Test Methods for Rockwell Hardness and the Rockwell Superficial Hardness of .

The Rockwell method has the following disadvantages: It is not always the most accurate hardness testing method, as even a small differential depth measurement error can lead to a significant error in the calculated hardness value.For Rockwell Hardness Scale C (HRC): Typically, the sample should be at least 0.6 to 1.0 mm thick. For Rockwell Hardness Scale B (HRB): Typically, the sample should be at least 0.8 to 1.6 mm thick. Strengths and Limitations of Rockwell Hardness Test. The following are some of the strengths and limitations of Rockwell hardness test:

rockwell hardness test calculation

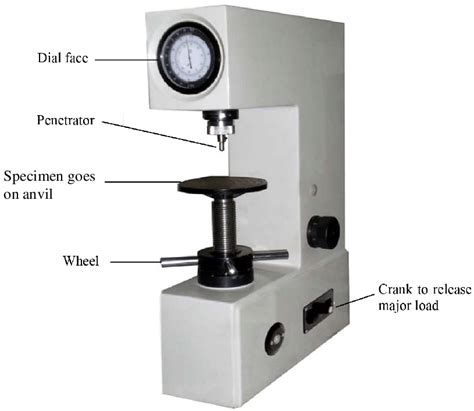

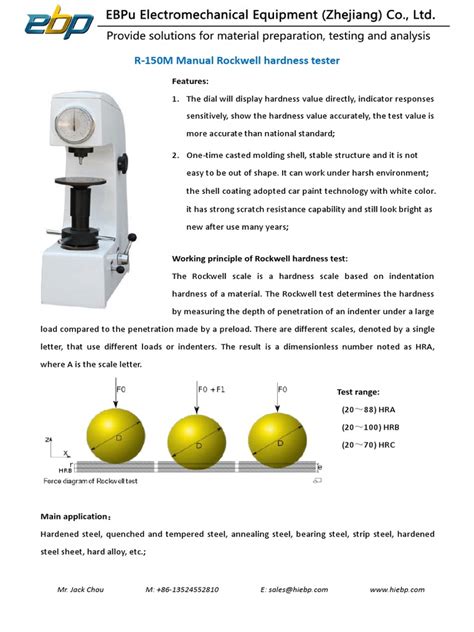

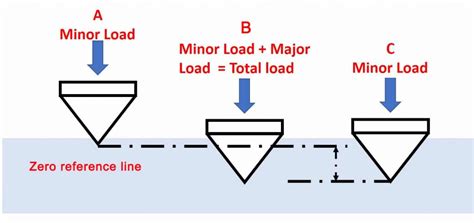

Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery of substandard product. This could have detrimental and catastrophic effects on the performance and the integrity of the goods they are used in.In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls.How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? Interpreting the Results with a Rockwell Hardness Test Chart; How to Calibrate a Rockwell Hardness Tester; What is the Standard for the Rockwell Hardness Test? Advantages and Disadvantages Of the Rockwell Hardness Test. Advantages Of Rockwell Hardness Test. 1.

rockwell hardness scale pdf

The drawback of the Rockwell test is that the indenter travel is limited to 100 Rockwell points or 0.2 millimeter. This limitation requires different combinations of test force and indenter shapes to accommodate the hardness of all the possible materials to be tested. What Are the Limitations of the Rockwell Testing Systems? The Rockwell Testing systems depend on the material that is being tested including the hardness, thickness, indentation positioning, and scale limitations on the materials that are being tested.TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 . If you are interested in obtaining a complete understanding and holistic background of the Rockwell hardness test, we recommend diving deeper into the ASTM E18-20 Standard Test Methods for Rockwell Hardness and the Rockwell Superficial Hardness of .

The Rockwell method has the following disadvantages: It is not always the most accurate hardness testing method, as even a small differential depth measurement error can lead to a significant error in the calculated hardness value.For Rockwell Hardness Scale C (HRC): Typically, the sample should be at least 0.6 to 1.0 mm thick. For Rockwell Hardness Scale B (HRB): Typically, the sample should be at least 0.8 to 1.6 mm thick. Strengths and Limitations of Rockwell Hardness Test. The following are some of the strengths and limitations of Rockwell hardness test:Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability.

iso 6508 1 2023 pdf

how to calibrate a refractometer schuco 5711-2020

how to calibrate a refractometer veterinary

how to calibrate a refractometer with calibration fluid

how to calibrate a salinity refractometer

In polyalphabetic substitution ciphers where the substitution alphabets are chosen by the use of a keyword, the Kasiski examination allows a cryptanalyst to deduce the length of the keyword. Once the length of the keyword is discovered, the cryptanalyst lines up the ciphertext in n columns, where n is the length of the keyword. Then each column can be treated as the ciphertext of a monoalphabetic substitution cipher. As such, each column can be attacked with frequency analysis

limitation on rockwell hardness test|rockwell hardness test calculation